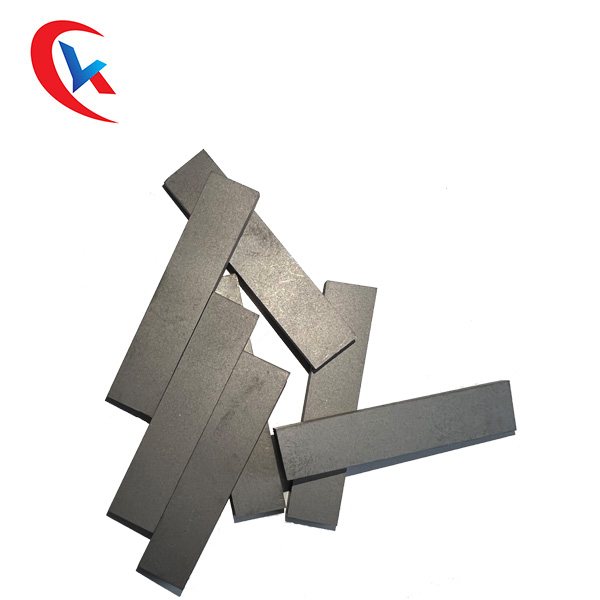

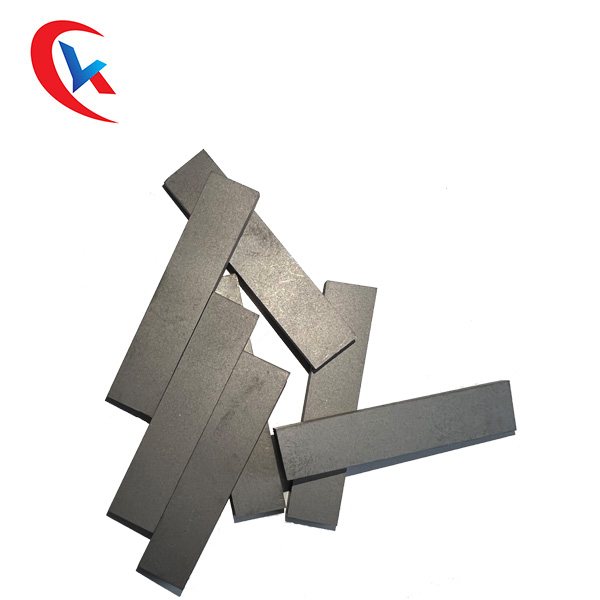

3*60*12MM High Hardness, Good Weldability, High Wear Resistance

Tungsten Carbide Strips

Product Details

| Product | Tungsten Carbide Strip |

| Usage | The Thick Cemented Carbide Plate Is Mainly Used To Make High-end

High-quality Cemented Carbide Molds, While The Thin Cemented

Carbide Plate Is Mainly Used To Make Wear-resistant Cemented

Carbide Blades |

| Brand | LIAN XIANG |

| Dimension | 2*60*12 |

| Country of Origin | ChengDu China |

| Advantage | High Hardness, Good Weldability, High Wear Resistance |

Use Of Carbide Blank Board

The hard alloy plate can be divided into thick plate and thin

plate. The thick hard alloy plate is mainly used to make high

quality hard alloy die, and the thin hard alloy plate is mainly

used to make wear-resisting hard alloy blade. The material

properties of thick cemented carbide sheet are very different from

those of thin cemented carbide sheet, so they are not

interchangeable in use.

Production Process Of Carbide Blank Board

Powder making → according to the requirements of the use of formula

→ wet grinding → mixing → grinding → drying → sieving → after

adding molding agent → drying → sieving after making the mixture →

granulating → pressing → forming → sintering → forming (blank)→

flaw detection inspection → packaging → storage

Product Pictures

Packaging & Shipping

1.We will choose the right package according to the shape of the

product. Usually choose foam plastic, cartons, large cartons,

professional plastic packaging boxes and so on.

2.According to your choice or our recommendation of the best

transportation plan.

FAQ

Q1. What is your advantage ?

A:We have the best factory to produce for you,could guarantee the

price is the most competitive. BEGUN carbide was recognized by

market, it widely used for Chinese big project.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% balance before delivery. We'll show

you the photos of the products and packages before you pay the

balance.

Q3. Could you offer OEM and ODM service?

A:That is ok ,we have more than 7years experience in OEM service.

professional R&D department is ready to design products to fit

your specifications,they can offer the professional advice and CAD

drawings(3D) for you!

Q4. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but

the customers have to pay the sample cost and the courier cost

Q5. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery. Our production is based

on ISO9001,we have more than 10 years experience of QC team and

strictly quality control system in our production process.

Q6. What about the package?

A.It can make as the you need and depend on the products shapes.

Generally, we can provide iron drum, carton, wooden case, and bag

packages.

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our

customers benefit ;

2. We respect every customer as our friend and we sincerely do

business and make friends with them, no matter where they come

from.

About Us

Chengdu Lianxiang New Materials Co., Ltd. is located in Sichuan

Chengdu Pixian County. Main carbide materials, (cold pier, bar,

sheet, mines, woodworking blade, welding blade, machine blade,

electronic specifications board, non-standard, etc.) hard alloy

moulds, (cold pier, powder metallurgy die, drawing die, etc.)

carbide internal and external research, flat grind, cut, discharge,

processing, product such as gigantic should treatment etc. In

hardware, tools, a mold industry recognized by our customers.

Companies adhering to the "first-class quality assurance, maintain

a level of credibility" business philosophy, adhere to the

"customer first" principle to provide our customers with quality

services. Welcome calls to negotiate business!